Our Journey Towards In-House Production

Last July I wrote an update article on some big changes within Dog Quality which involved bringing the assembly of our Dogger stroller and some of the sewing for our Washable Wonders dog incontinence products in-house. The purpose was to give us more control over the manufacturing of our products, to improve quality and to try and better meet the growing demand. So much has happened over the past 8 months that I wanted to share where we are now and how things have changed even more.

Dogger stroller production

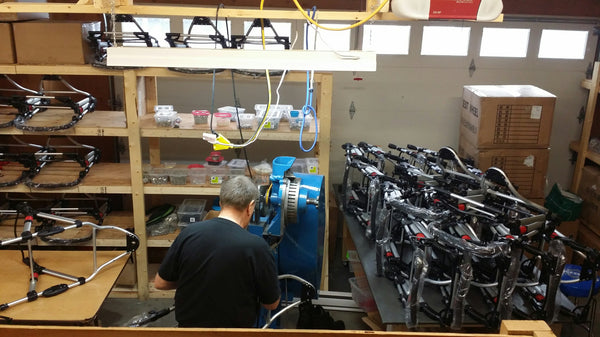

Bringing 100% of the assembly of our Dogger strollers in-house has not been without its challenges. Now that we are working with parts and components on a granular level we have been able to identify improvements along the way and modifications to parts that have significantly improved the overall quality of the product. The downside is that because of all the extra time we are putting into the parts themselves, we are unable to produce our strollers fast enough to meet the growing demand. The good news is we are well on our way. Many of the modifications we have identified are being made to the parts in a permanent way and in some cases, completely new types of parts/components are being used which will make the process much more efficient moving forward. There is an enormous amount of pride that goes into each and every stroller and hearing the difference the Dogger is making in the lives of senior dogs is what keeps us going! It may not be easy, but it is certainly worth it!

Bringing 100% of the assembly of our Dogger strollers in-house has not been without its challenges. Now that we are working with parts and components on a granular level we have been able to identify improvements along the way and modifications to parts that have significantly improved the overall quality of the product. The downside is that because of all the extra time we are putting into the parts themselves, we are unable to produce our strollers fast enough to meet the growing demand. The good news is we are well on our way. Many of the modifications we have identified are being made to the parts in a permanent way and in some cases, completely new types of parts/components are being used which will make the process much more efficient moving forward. There is an enormous amount of pride that goes into each and every stroller and hearing the difference the Dogger is making in the lives of senior dogs is what keeps us going! It may not be easy, but it is certainly worth it!

Dog diaper production

This year some of our biggest changes center around the production of our Washable Wonders dog diapers, pads and belly bands. Last year we made the decision to bring some of the sewing in-house because we were finding that our larger productions, which were outsourced, were taking too long. However what we quickly realized was that as the demand for our incontinence products continued to increase, even with daily sewing efforts ,we could not keep up while we awaited the larger productions to arrive. In fact by the time we would receive our shipments, we had so many people waiting that we would sell out within a few weeks and would then be back in the same situation all over again. and it was far more than our modest sewing efforts could offset. And knowing how urgently dog parents need our diapers, belly bands and pads, running out of product becomes deeply painful because I know we are letting people and dogs down.

In January of this year I made the decision to bring all of the sewing in-house. Rather than investing more money into these larger productions that take up to 4 months to be completed I instead decided to put the money into equipment, people and fabric.  It has taken us some time to find the right people, machines and fabric but we have made great progress. We have a small but amazing sewing team who puts their heart and soul into making these products. They continue to find better and more efficient ways to make our diapers which is really starting to payoff. We have also been working with a new fabric supplier out of the United States who I am very excited about. They have been busy matching our fabrics and colors and we will begin moving over to their fabrics over the next few months.

It has taken us some time to find the right people, machines and fabric but we have made great progress. We have a small but amazing sewing team who puts their heart and soul into making these products. They continue to find better and more efficient ways to make our diapers which is really starting to payoff. We have also been working with a new fabric supplier out of the United States who I am very excited about. They have been busy matching our fabrics and colors and we will begin moving over to their fabrics over the next few months.

We still have a lot of work ahead of us for both product lines; the Dogger and our Washable Wonders, since we need to expand both departments even more, but for now we are restricted by space and need to relocate to a bigger facility to accommodate more equipment and team members. We are actively looking and I hope to have some good news in this area very soon.

I love sharing our milestones and updates with all of you because while it is difficult to endure all the growing pains that come with change, the results are amazing. I am overwhelmed with pride to take something we made and pack it up for a customer to use on or with their dog.  It is a dream come true to see these very special products being made here by us. It is hard not to be super excited about the future. In addition to resolving our supply issues and improving quality, having the ability to make our own products means we will be able to introduce new products more easily such as the Big Dogger and amputee diapers.

It is a dream come true to see these very special products being made here by us. It is hard not to be super excited about the future. In addition to resolving our supply issues and improving quality, having the ability to make our own products means we will be able to introduce new products more easily such as the Big Dogger and amputee diapers.

I have had to learn a great deal about patience and perseverance throughout, but I know in my heart these changes are essential for the continued success of Dog Quality and they are the best way I know how to ensure that we get every dog that needs us, the products that can make a real difference in their lives.

We hope that you will share in our excitement and our vision and I thank you from the bottom of my heart for believing in us, supporting us and being patient with us. We won't let you down!

Ann-Marie Fleming is the Founder & CEO of Dog Quality, a provider of products focused on improving the quality of life for older dogs.